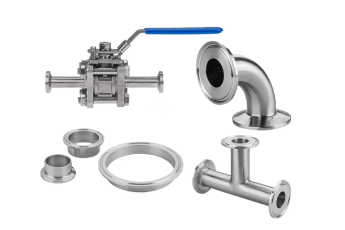

A range of hygienic tri-clamp fittings, including pipes, gaskets, valves, blank caps, and more.

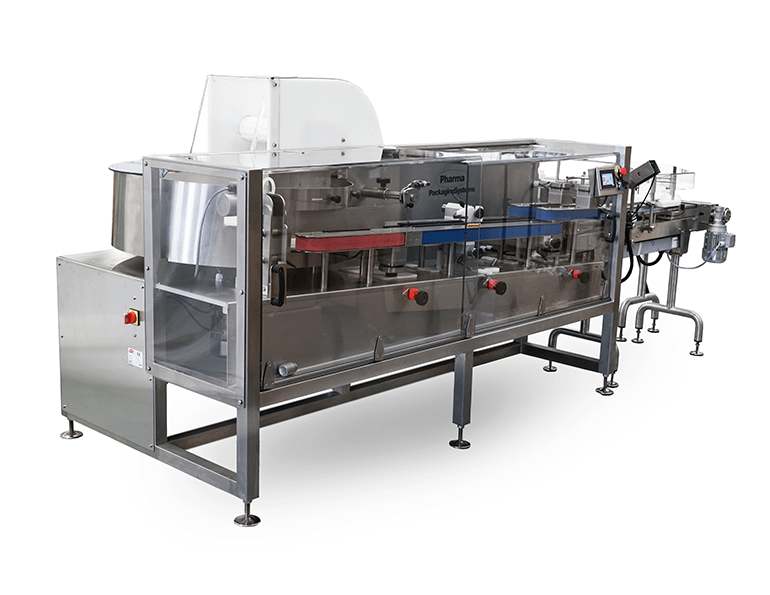

The PPS bottle unscrambler is not a typical belt and hook type unscrambler. Instead this ultra reliable unscrambler is extremely compact yet is capable of high speeds. The M1000 model (or M1200 for larger bottles or faster speeds) is the perfect companion to our PPS counters; the unscrambler will operate up to 125 bottles per minute on 200ml round containers and can be equipped with ionized air bottle inverting cleaner. Also available are models with a built-in cleaner.

Bottles are placed in the main hopper where a live bottom conveyor belt transfers all bottles to a compact elevator (there are no dead zones). This system allows full boxes of bottles to be loaded and all will be fed out. Bottles are elevated to a rotary sorter from which they exit end-to-end. Containers progress to the extra-wide orienter belts where they are accelerated for separation, are turned for neck trailing, and are temporarily turned upside down for cleaning (optional container inverting system). The vacuum is extra or plant vacuum can be used. The containers exit onto any standard tabletop conveyor. The unscrambler is very easy to changeover. Toolless, dials featuring readouts, HMI for all speed settings such as servo-motors for belts and turntables. Everything is saved to memory in the recipe management system.

Test section for content copy in the middle of the page.

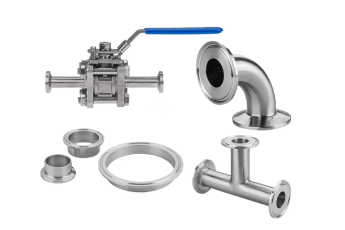

A range of hygienic tri-clamp fittings, including pipes, gaskets, valves, blank caps, and more.

Also known as bag and sachet makers, these high-performance machines are designed to make, fill, and seal a various selection of pouches in one automatic process. The OMAG CO uses intermittent motion to package solid, powdery, granular, liquid, and pasty products in heat-sealed bags on 3 sides or on 4 sides, including in doy-packs and stand-up versions. These machines can also be built to include multiple dosing stations to increase production or customization with options to apply spouts and tear notches to the bags or sachets.

A range of stainless steel funnels, conical strainers and funnels with built-in fixed strainers, which are available in 304 grade stainless steel.

Manufactured from 304 grade stainless steel, this simple stainless steel capsule counting tray has corrugations that allow ten rows of ten capsules up to 8mm diameter to be counted quickly and easily.

16773 Blvd Hymus Kirkland (Montreal),

QC Canada, H9H 3L4

Phone 514-630-1818