Contact parts cart for cleaning and storage. Models available for counters, fillers, tablet lift, and rotary cappers.

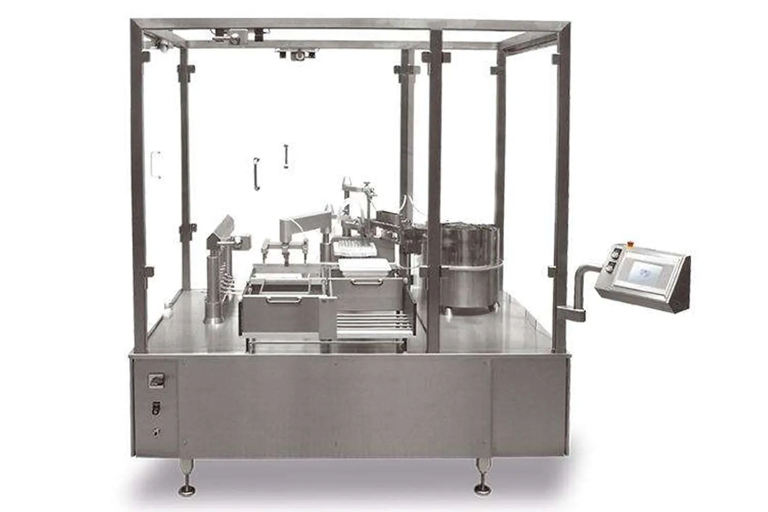

ROTA’s automatic filling and stopping machines for bulk or nested syringes, the RSM02-10 models, are highly accurate, aseptic, and designed to meet the diverse needs of pharmaceutical companies from start-up to mass production. Options can include plunger insertion, finger protector, and labeler – all-in-one!

The RSM series machines incorporate state of art servomotor technology to guarantee gentle transport, filling from the bottom up, and rubber plunger insertion. The syringe filling equipment meets all cGMP regulations, comes with deliders for lid removal, and are designed to guarantee a perfect laminar airflow path over each machine’s working area.

“Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.”

Contact parts cart for cleaning and storage. Models available for counters, fillers, tablet lift, and rotary cappers.

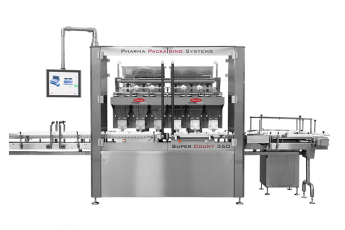

The PPS SuperCount 360 Dual Lane Counter is a high-speed tablet counter offering proven product feed technology with the latest in electronic controls and infrared count heads for extreme accuracy. This 36-track counter can accurately handle all pill types including translucent and opaque products. Designed for ultimate product control, you can change recipes on the fly and easily teach the machine to learn to count a variety of differently sized products. Counters are available in various configurations including 12-track, 18-track, 24-track, and 36-track. All counters offer toolless changeover for efficiency and ease.

The FM70 wrapping machine can wrap multilayer bundles. The MB60 is a small and compact wrapping machine designed to overwrap a single carton. Both high-quality machines are capable of pleat wrapping your products, and both are designed to easily integrate with our cartoners.

Tailored for precision, our standard Gummy Counter is expertly crafted to count larger quantities of gummies into bottles in smaller volumes. The VitaGummy™ can also be customized for specific applications, excelling at dispensing smaller quantities into pouches or canisters. Recognizing that each application demands unique settings, entrust us as your top supplier for gummy packaging equipment. We are committed to collaborating with you to pinpoint the optimal gummy counting solution tailored to your specific needs.

16773 Blvd Hymus Kirkland (Montreal),

QC Canada, H9H 3L4

Phone 514-630-1818