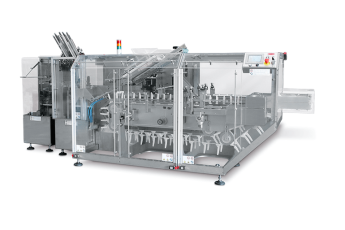

The filling needle is moved automatically until all vials in the tray are filled. Our automatic tray filler is easy to program for different tray configurations, the diving needle eliminates splashes on the outside of the containers, and the whole system is simple to set up. It is also designed to work with our peristaltic pump.