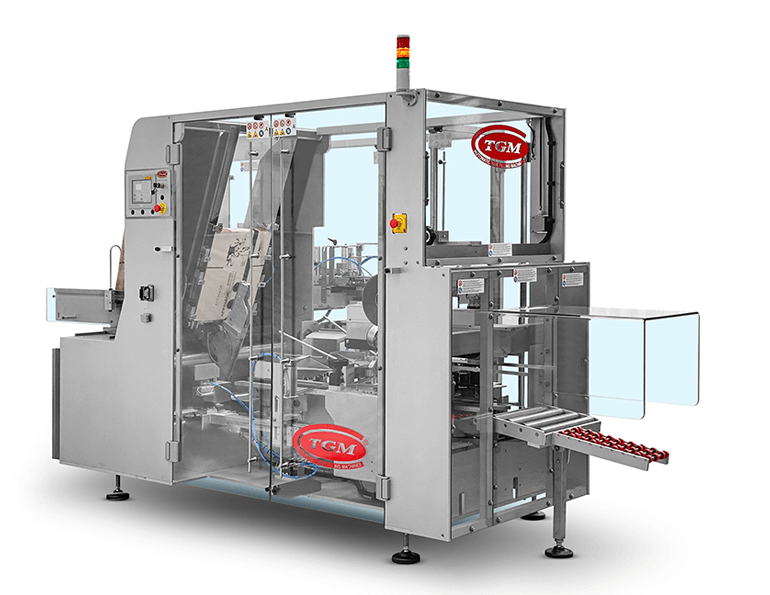

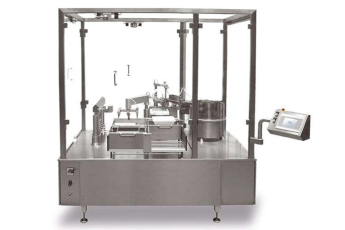

The PPS VitaCount is an affordable and automated solution designed for tablets, soft gels, caplets, capsules, and pills. This counter combines our proven product feed technology with electronic controls and infrared count heads as used on our larger counters. The VitaCount has been optimized for applications where large products make up the vast majority of the production.