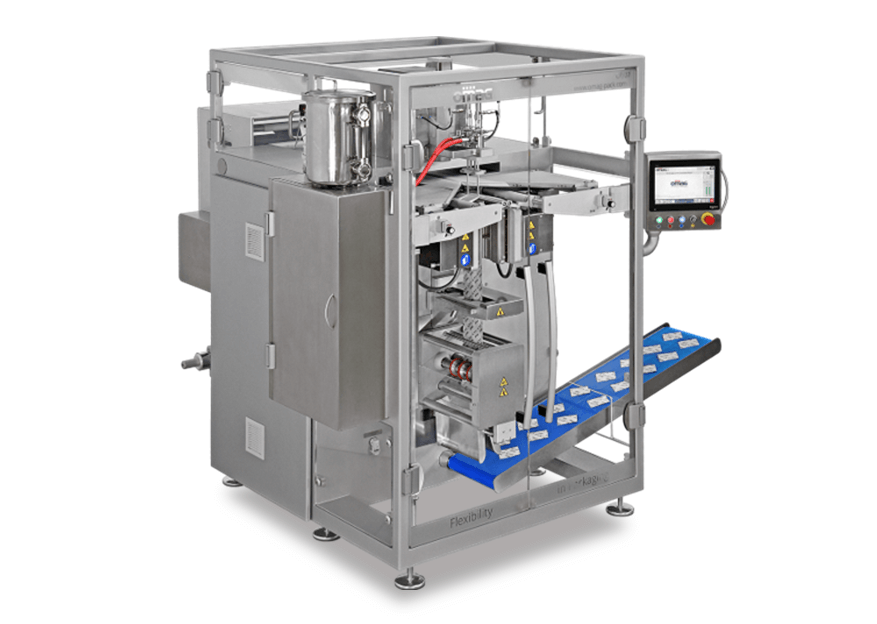

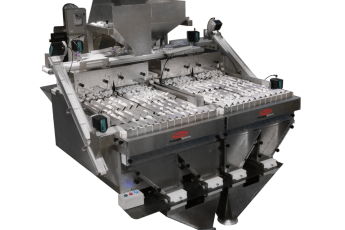

The PrecisionCount is a high-speed, electronic counter designed to count industrial products such as soap pouches. This counting line features the same proven electronic count eyes as found on all of our counters. Upon alignment into singular files, the product undergoes precise counting with strategically placed gates halting the process once the designated count is reached. This pause endures until the containers, ready to receive the products, are accurately indexed. Notably, each of the two counters boasts 12 count eyes, each equipped with 12 emitters and receivers, scanning at an impressive rate of 34,000 times per second.

Fashioned from stainless steel, the main cabinet incorporates a sizable access panel, facilitating effortless entry to the electrical panels and pneumatic controls.