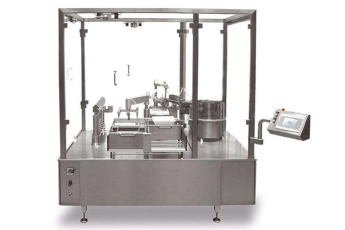

ROTA’s automatic filling and stopping machines for bulk or nested syringes, the RSM02-10 models, are highly accurate, aseptic, and designed to meet the diverse needs of pharmaceutical companies from start-up to mass production. Options can include plunger insertion, finger protector, and labeler – all-in-one!