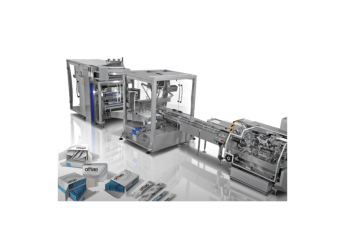

Stick Pack, Sachet, and Pouch Machines deliver performance. Quality, Versatility, Stand Alone Machines, and Complete Line Solutions. Let us configure the right solution for your application. OMAG machines always feature easy-to-use controls, quick changeover, an extensive range of options to suit the most complex products and applications, and can be integrated enabling us to provide you with turnkey solutions with a single point of responsibility from foil roll to case packing. Now with local service support options!