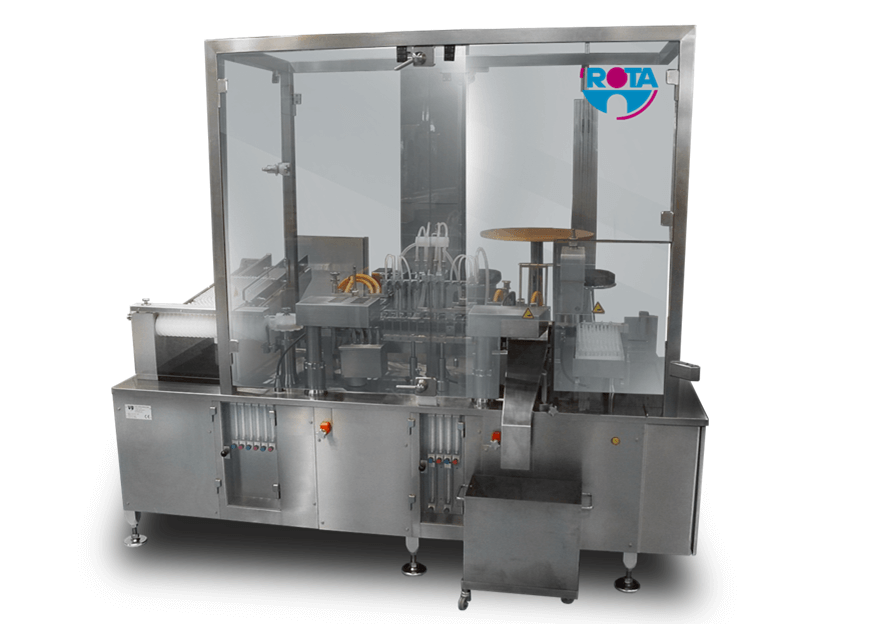

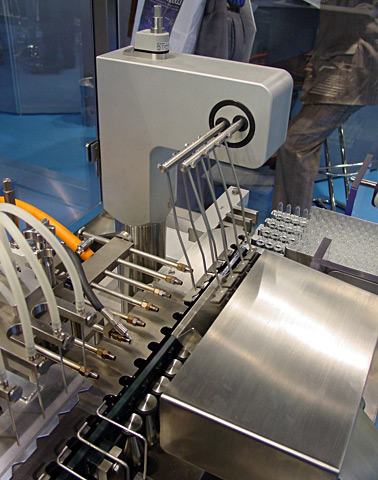

The PPS bottle unscrambler is not a typical belt and hook type unscrambler. Instead this ultra reliable unscrambler is extremely compact yet is capable of high speeds. The M1000 model (or M1200 for larger bottles or faster speeds) is the perfect companion to our PPS counters; the unscrambler will operate up to 125 bottles per minute on 200ml round containers and can be equipped with ionized air bottle inverting cleaner. Also available are models with a built-in cleaner.