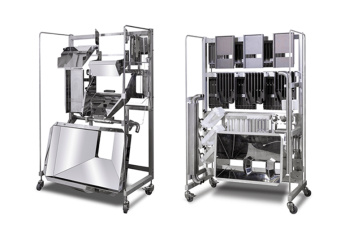

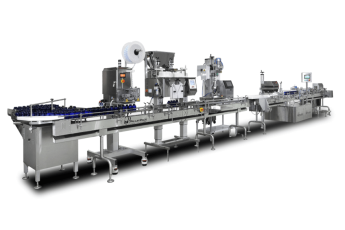

The MiniLine™ is a modular, complete counting line meticulously designed to grow alongside your business. Begin with a semi-automatic counting line and, as your production needs increase, upgrade to a fully automatic counting system. The MiniLine™ fills tablets, soft gels, caplets, capsules, other pill-types into bottles. This modular system is crafted for flexibility and cost efficiency, allowing you to augment and integrate various machines as your pill packaging needs increase. Your investment remains future-proof – no need to purchase an entirely new line even as production levels soar.