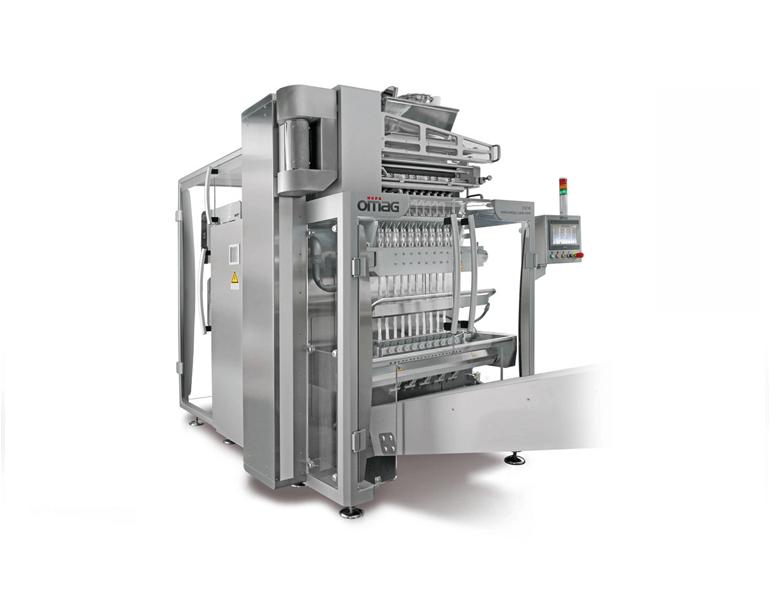

The FM70 wrapping machine can wrap multilayer bundles. The MB60 is a small and compact wrapping machine designed to overwrap a single carton. Both high-quality machines are capable of pleat wrapping your products, and both are designed to easily integrate with our cartoners.