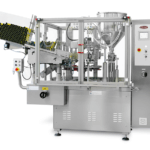

The ROTA Ampoule Filler, including the R941, R960, R980, and R921 models, is an advanced machine designed for the sterile filling and closing of ampoules in pharmaceutical settings. These machines, featuring Monoblock construction with indexing starwheels, handle filling, sealing, and stoppering stations efficiently. A comprehensive list of optional features and accessories allows the machine to meet the individual requirements of each customer and application. We also have dual function machines that can also fill and close vials as well as ampoules, providing you with the greatest flexibility.