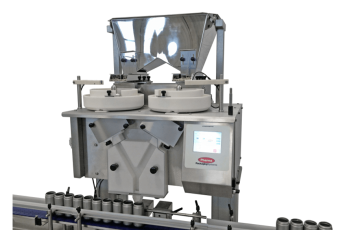

The SC180 Pharmaceutical Counter is a high-speed pill counter for tablets, caplets, soft gels, and capsules. This 18-track counter can accurately handle all pill types including translucent and opaque products. Designed for ultimate product control, you can change recipes on the fly and easily teach the machine to learn to count a variety of differently sized products. Our 18-track counter is actually a triple 6 track. The advantage of this design is that each set of 6 tracks can fill an individual bottle, resulting in significantly faster output speeds. Counters are available in various configurations including 12-track, 18-track, 24-track, and 36-track. All counters offer toolless changeover for efficiency and ease.