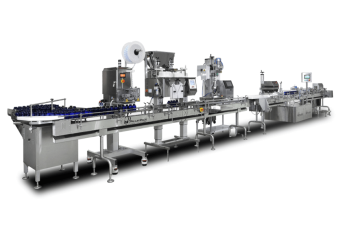

Our Gummy Counters are constructed to handle gummies with variations in shape and size while still delivering the smoothness associated with bulk auto loading and continuous flow. The GummyCount™ can be easily scaled up or down to accommodate changes in product demand. Speed options for our gummy manufacturing equipment range from 50 bottles per minute on a 50-count of medium-sized gummies to 100 bottles per minute filling 6 bottles at a time.