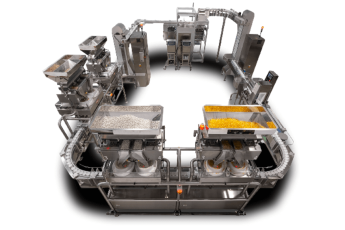

A simple method for visible particulate detection in vials, syringes, bottles, and ampoules. Our Apollo machines are US Pharmacopoeia USP chapter 41 (1790), section 6.1 compliant. Black and white backgrounds with LED lighting with 50,000 hours of service life. Low price and quick delivery.