These containers are designed and manufactured to comply with Good Manufacturing Practices (GMP) for material handling, storage of raw materials, mixing and blending, transportation of intermediates, and liquid storage.

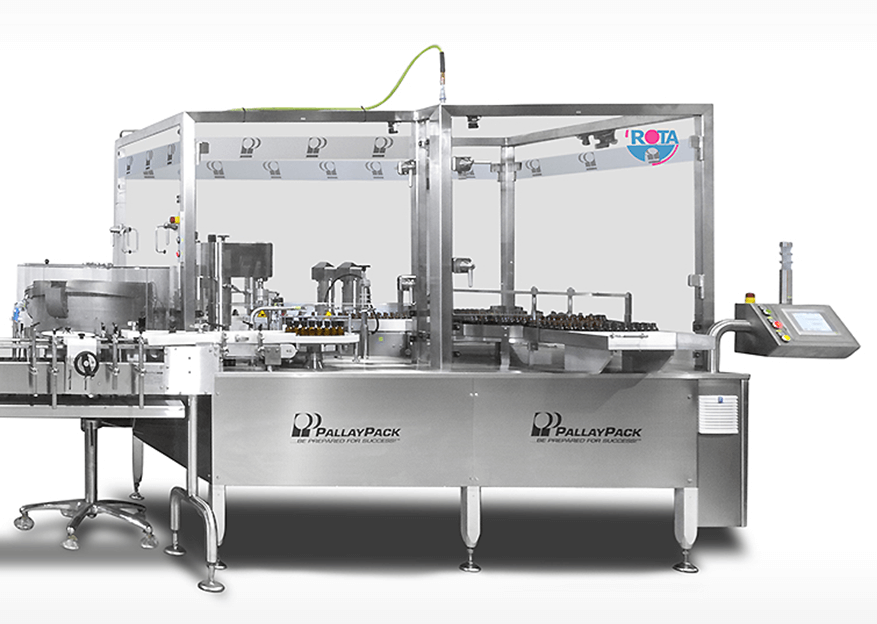

ROTA’s FLR Pharmaceutical Vial Filler Machines can be configured to fill, insert a stopper or plug, crimp cap, or screw cap depending on the application. These efficient solutions offer versatile dosing options, prevent waste, and accommodate various vial filling and closing methods to ensure precise and profitable operations for your pharmaceutical needs.

Vial packaging machine models range from single fill to dual filling options with outputs of up to 300 vials per minute, accommodating vial sizes from 2ml to 100ml. Perfect aseptic filling machine to handle diagnostic products and reagents.

“Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.”

These containers are designed and manufactured to comply with Good Manufacturing Practices (GMP) for material handling, storage of raw materials, mixing and blending, transportation of intermediates, and liquid storage.

Tailored for precision, our standard Gummy Counter is expertly crafted to count larger quantities of gummies into bottles in smaller volumes. The VitaGummy™ can also be customized for specific applications, excelling at dispensing smaller quantities into pouches or canisters. Recognizing that each application demands unique settings, entrust us as your top supplier for gummy packaging equipment. We are committed to collaborating with you to pinpoint the optimal gummy counting solution tailored to your specific needs.

A range of stainless steel containers, manufactured from 304 grade, and have an optional stainless steel lid for every size. They have crevice and pit-free interiors and are polished throughout. A range of optional modifications is available. 150ml – 6L containers are available as standard. The exceptional average surface finish of 0.4 micrometers Ra can be cleaned with alcohol-based disinfectants and in industrial dishwashers/autoclaves.

The filling needle is moved automatically until all vials in the tray are filled. Our automatic tray filler is easy to program for different tray configurations, the diving needle eliminates splashes on the outside of the containers, and the whole system is simple to set up. It is also designed to work with our peristaltic pump.

16773 Blvd Hymus Kirkland (Montreal),

QC Canada, H9H 3L4

Phone 514-630-1818