A range of stainless steel funnels, conical strainers and funnels with built-in fixed strainers, which are available in 304 grade stainless steel.

The Lifting Leaf Tablet/Capsule Counter enables quick and accurate counting of both coated and uncoated tablets and capsules. The counter has hygienic, durable stainless steel, anodized aluminum, and polycarbonate construction, and dispenses up to 100 tablets or capsules at a time, dependent on size.

Made to order and precisely match your samples. The counter is used as a scoop and pushed into a pile of tablets. The requisite number of tablets or capsules fall into the holes and the excess is shaken off. The counter is then tilted back and used as a chute for filling bottles.

“Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.”

A range of stainless steel funnels, conical strainers and funnels with built-in fixed strainers, which are available in 304 grade stainless steel.

The PallayCap Capper is an automatic capping machine that combines innovative design with unparalleled performance. The PallayCap I, II, and III models offer chuck capping, pick and place cap transfer, and a unique inline indexing system. Ideal for a diverse range of containers and closures, this capper operates at speeds ranging from 10 to 80 containers per minute, ensuring precision and efficiency in your packaging process.

No change parts counter suitable for tablets, capsules, soft gels, and pills. Available with a small hopper for the bulk product. An accurate count is automatically dosed into individual containers. All contact parts are removed without tools for cleaning. Simple set up and count adjustment.

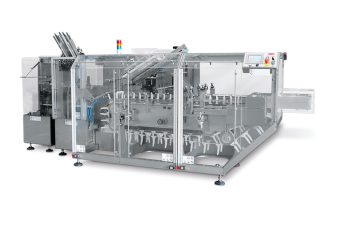

TGM offers a range of horizontal, automatic cartoning machines, each designed to cater to different production needs in industries like food, cosmetics, pharmaceuticals, and medical.

The Box90 is an intermittent motion horizontal cartoner suitable for use in medium to high volume production lines. The Box100 is an intermittent motion horizontal cartoner suitable for use in medium to high-speed production lines. The Box150 is a continuous motion horizontal cartoner suitable for use in high-speed production lines. The Box200 is a continuous motion horizontal cartoner suitable for use in high-volume production lines.

Each of these machines offers unique capabilities, making them suitable for a wide range of packaging needs. The choice of a specific model would depend on the specific requirements of the production line, including the type of product being packaged, desired speed, and the level of automation required.

16773 Blvd Hymus Kirkland (Montreal),

QC Canada, H9H 3L4

Phone 514-630-1818