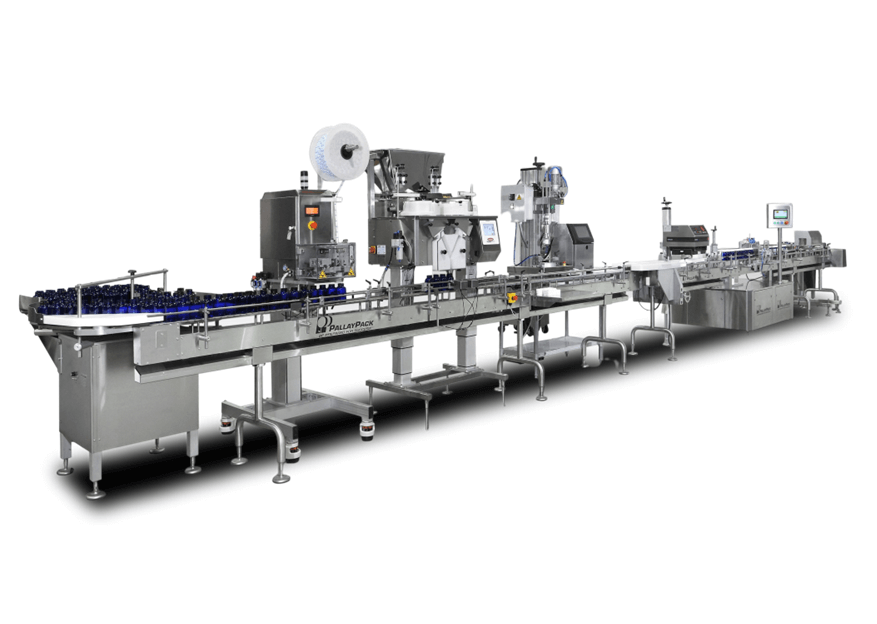

ROTA’s FLR Pharmaceutical Vial Filler Machines can be configured to fill, insert a stopper or plug, crimp cap, or screw cap depending on the application. These efficient solutions offer versatile dosing options, prevent waste, and accommodate various vial filling and closing methods to ensure precise and profitable operations for your pharmaceutical needs.