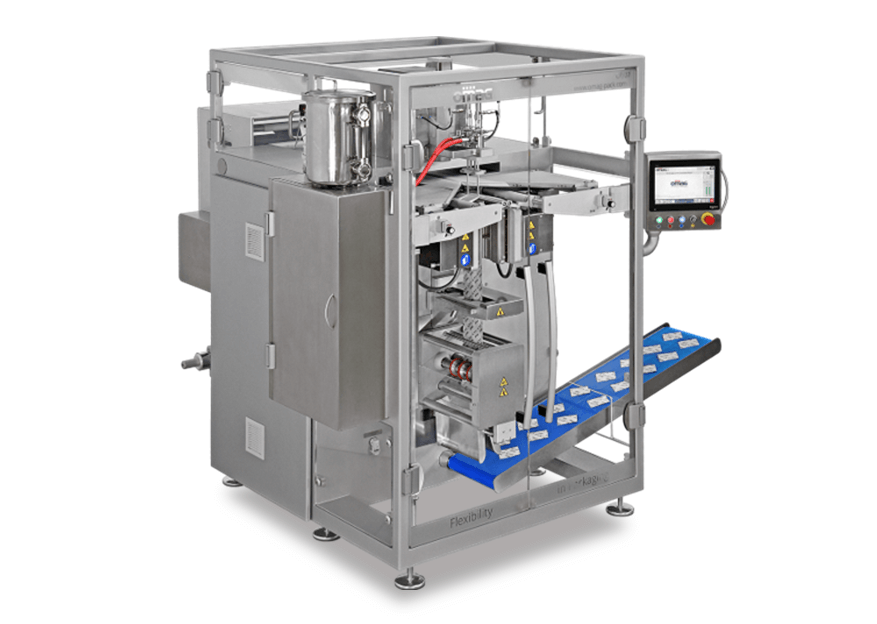

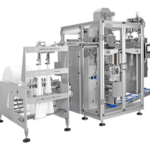

Highly accurate filler with rotary valve and piston pump is suitable for filling up to 1 liter of most products including viscous pastes and creams. Multiple attachments and easy cleaning make this a versatile addition to your lab, suitable for the widest range of containers and products. “Response” to all of your filling needs in the lab!