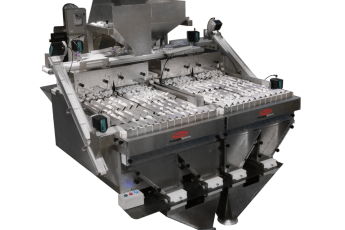

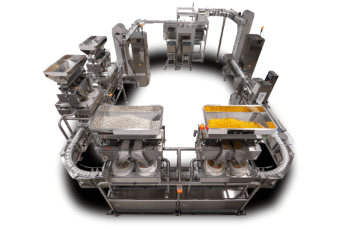

The Multipack Counter and Sachet System is a patent-pending supplement packaging system for feeding soft gels, tablets, capsules, caplets, and other pills into form-fill sachets without change parts. It’s the perfect solution for companies that manufacture pill packs, multivitamin packs, health supplement packs, and multi-dose pill packs. Specifically designed to ease complicated packaging, this system is built to be jam-free and handle soft gels even when sizes vary.