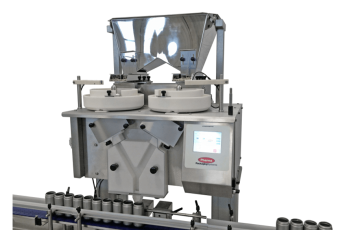

The PharmaCount 2-2 is the latest evolution in low volume electronic tablet counting. Available in semi-automatic and automatic configurations, this electronic counting system is counts and fills pills into bottles with reliability and high accuracy at speeds of up to 2,500 tablets per minute. Designed with the industry in mind, this automatic pill counter virtually eliminates problems with miscounts and jamming due to its state-of-the-art vision system.