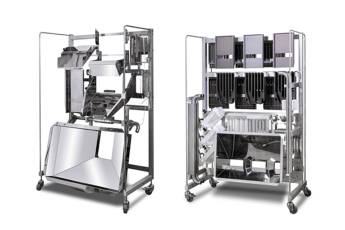

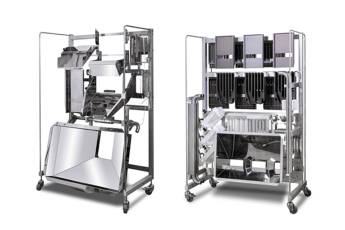

Contact parts cart for cleaning and storage. Models available for counters, fillers, tablet lift, and rotary cappers.

ROTA’s vial and ampoule washers offer advanced cleaning solutions for biotech and pharmaceutical applications, emphasizing quality and affordability. These machines can function as standalone units or as part of a complete processing line. The washers, available in various models from laboratory to high-speed continuous motion, feature seven washing cycles. Each cycle can be customized for air wash, rinse, or solution rinse, effectively managing recycled and virgin solutions. Each Rotary Washer model number refers to the theoretical output in units per minute, RW50, RW100, RW180, RW240, RW300, and RW400.

Our washers have a rotary design to reduce breakage and minimize cross-contamination through efficient movement between cleaning stations.

“Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.”

Contact parts cart for cleaning and storage. Models available for counters, fillers, tablet lift, and rotary cappers.

The C3 is a continuous motion sachet packaging machine that packs heat-sealed sachets on four sides using auger dosing or volumetric dosing. The C3 model is designed for packaging a broad range of products including solid, powdery, granular, liquid, and pasty, and is employed in a variety of sectors This machine model is produced in versions with 1 to 15 lanes, working with rolls of up to 1200mm. Special versions can be supplied on specific request.

Discover our range of automatic cosmetic tube filling machines, exclusively designed for the precise dosing and capping of mascara, lip gloss, and various cosmetic products. With remarkable versatility, these machines effortlessly accommodate bottles of irregular shapes, metal bottles, and plastic bottles to ensure a seamless and efficient packaging process for your cosmetic line.

TGM vertical cartoning machines are designed for manual or automatic loading of various types of cartons. The Box80V is a highly versatile vertical cartoner that can handle different products with several components thanks to manual loading of the product in the carton, and the Box90V is a highly versatile continuous motion vertical cartoner with fully automatic product loading and numerous accessories. Our vertical cartoners’ range of manual to automatic operation, high throughput, and versatility in handling different product types and packaging materials make them valuable assets for companies looking to optimize their packaging processes.

16773 Blvd Hymus Kirkland (Montreal),

QC Canada, H9H 3L4

Phone 514-630-1818