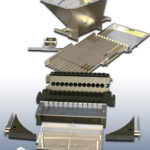

ROTA Complete Vial and Ampoule Packaging Lines meet the highest pharmaceutical standards for aseptic products. Designed by ROTA in Germany, these aseptic turnkey packaging lines offer seamless integration of washing, filling, stopping, crimp and screw capping, labeling, and particle inspection, all within a compact and flexible production system. With exceptional efficiency, reliability, and customizable options, ROTA Packaging Lines provide the ideal solution for pharmaceutical companies seeking sterile and particle-free packaging solutions. Each of these machines is also available stand-alone or ready for integration with existing equipment.