Specialized equipment used in the pharmaceutical industry for the purpose of mixing and blending various ingredients to create pharmaceutical products.

The PallayCap Capper is an automatic capping machine that combines innovative design with unparalleled performance. The PallayCap I, II, and III models offer chuck capping, pick and place cap transfer, and a unique inline indexing system. Ideal for a diverse range of containers and closures, this capper operates at speeds ranging from 10 to 80 containers per minute, ensuring precision and efficiency in your packaging process.

The PallayCap Capper is specifically designed to address the challenges of precise capping in the 0-80 bottles per minute range. It eliminates issues such as loose or cross-threaded caps, making it suitable for containers with unique shapes, soft materials, or challenging cap application methods.

Specialized equipment used in the pharmaceutical industry for the purpose of mixing and blending various ingredients to create pharmaceutical products.

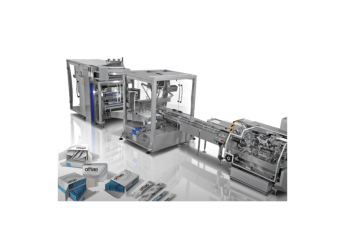

TGM vertical cartoning machines are designed for manual or automatic loading of various types of cartons. The Box80V is a highly versatile vertical cartoner that can handle different products with several components thanks to manual loading of the product in the carton, and the Box90V is a highly versatile continuous motion vertical cartoner with fully automatic product loading and numerous accessories. Our vertical cartoners’ range of manual to automatic operation, high throughput, and versatility in handling different product types and packaging materials make them valuable assets for companies looking to optimize their packaging processes.

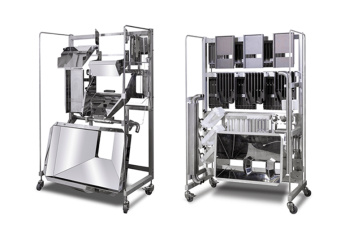

Contact parts cart for cleaning and storage. Models available for counters, fillers, tablet lift, and rotary cappers.

Stick Pack, Sachet, and Pouch Machines deliver performance. Quality, Versatility, Stand Alone Machines, and Complete Line Solutions. Let us configure the right solution for your application. OMAG machines always feature easy-to-use controls, quick changeover, an extensive range of options to suit the most complex products and applications, and can be integrated enabling us to provide you with turnkey solutions with a single point of responsibility from foil roll to case packing. Now with local service support options!

16773 Blvd Hymus Kirkland (Montreal),

QC Canada, H9H 3L4

Phone 514-630-1818