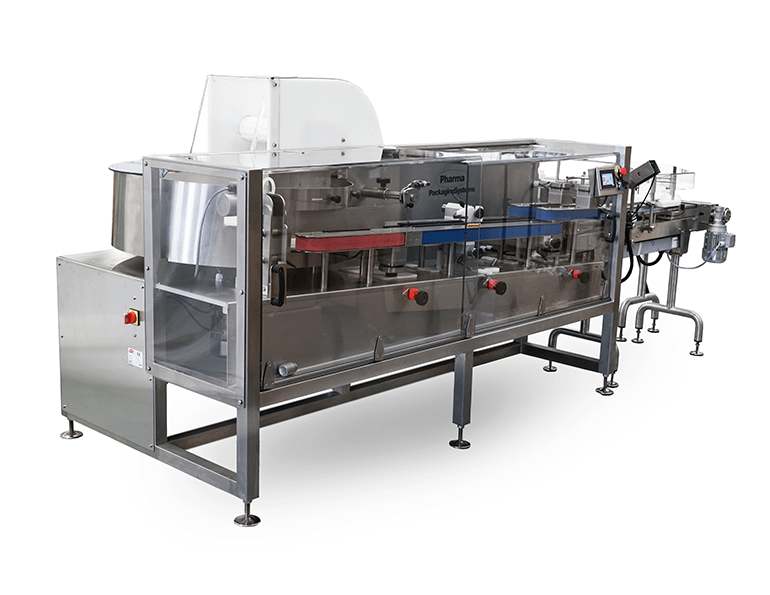

This machine is designed to package a broad range of products: solid, powdery, granular, liquid, and pasty, and is employed in a variety of sectors that used single-dose packing.

The machine uses a single roll of heat-sealing film, which is pre-cut in the number of packaging lines.

A tubular sleeve is created out of each strip, and then sealed lengthwise; the horizontal sealing unit forms the stick.