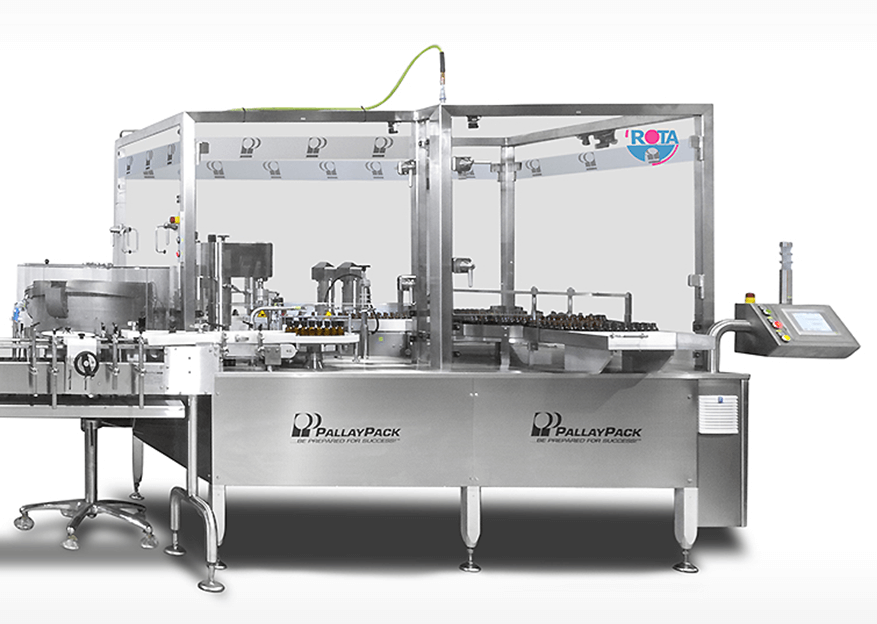

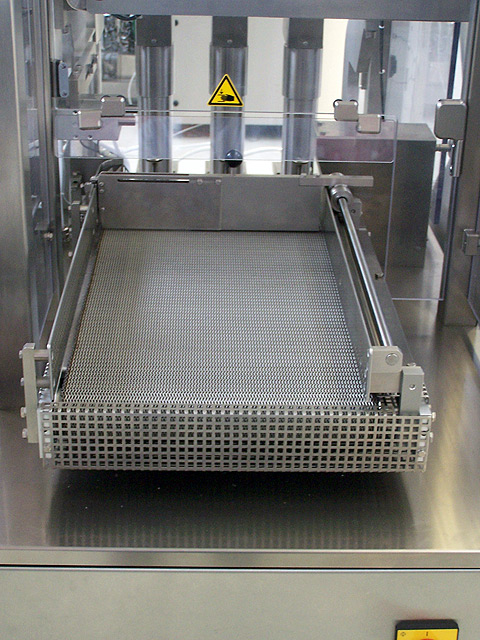

ROTA’s vial and ampoule washers offer advanced cleaning solutions for biotech and pharmaceutical applications, emphasizing quality and affordability. These machines can function as standalone units or as part of a complete processing line. The washers, available in various models from laboratory to high-speed continuous motion, feature seven washing cycles. Each cycle can be customized for air wash, rinse, or solution rinse, effectively managing recycled and virgin solutions. Each Rotary Washer model number refers to the theoretical output in units per minute, RW50, RW100, RW180, RW240, RW300, and RW400.