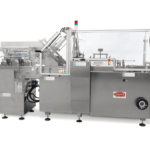

Rotary chuck type cappers virtually eliminate missing caps and cross-threaded caps. Improve and maintain cap application torque throughout production without adjustments. PallayPack cappers are compact and require less change parts since one set can be used for a range of bottles and caps.

Changeover is fast and when finished requires no further adjustment to dial in the torque. Rotary cappers are recommended when production speed is over 60 bottles per minute and for longer production runs.