A range of stainless steel funnels, conical strainers and funnels with built-in fixed strainers, which are available in 304 grade stainless steel.

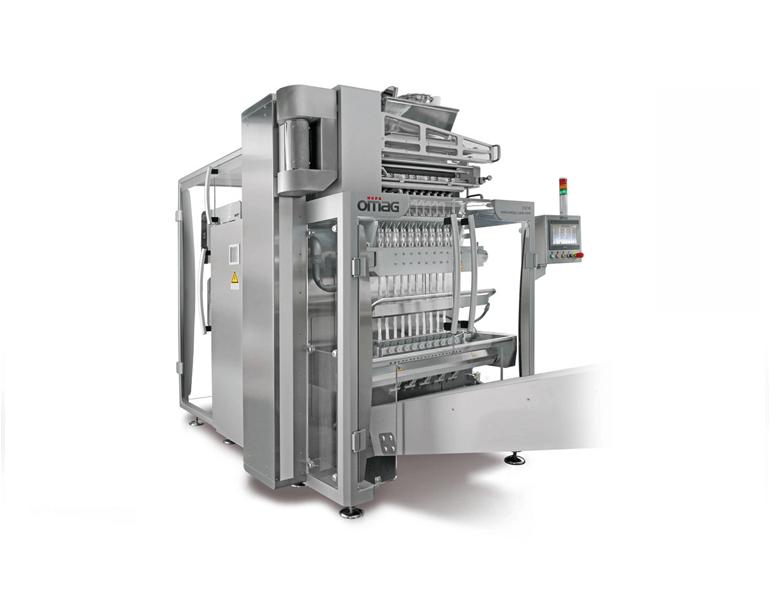

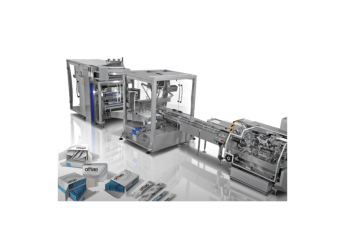

The latest vertical multi-lane intermittent motion machines efficiently package various products into stick-pack form: tubular bags with three side seals. Stick-packs offer a sleek design and ease of use, while also reducing the amount of packing film required. This machine is suitable for businesses seeking to package products in smaller formats without compromising on design and packaging quality. The stick pack equipment’s adaptable dosing system and the option to include any type of marking unit enhance efficiency, potentially shortening cycle times and boosting production rates.

The CS model is versatile, capable of packaging a diverse range of items — solid, powdery, granular, liquid, or pasty — into stick-packs or custom-shaped packets.

A range of stainless steel funnels, conical strainers and funnels with built-in fixed strainers, which are available in 304 grade stainless steel.

The PPS VitaCount is an affordable and automated solution designed for tablets, soft gels, caplets, capsules, and pills. This counter combines our proven product feed technology with electronic controls and infrared count heads as used on our larger counters. The VitaCount has been optimized for applications where large products make up the vast majority of the production.

Stick Pack, Sachet, and Pouch Machines deliver performance. Quality, Versatility, Stand Alone Machines, and Complete Line Solutions. Let us configure the right solution for your application. OMAG machines always feature easy-to-use controls, quick changeover, an extensive range of options to suit the most complex products and applications, and can be integrated enabling us to provide you with turnkey solutions with a single point of responsibility from foil roll to case packing. Now with local service support options!

ROTA Complete Vial and Ampoule Packaging Lines meet the highest pharmaceutical standards for aseptic products. Designed by ROTA in Germany, these aseptic turnkey packaging lines offer seamless integration of washing, filling, stopping, crimp and screw capping, labeling, and particle inspection, all within a compact and flexible production system. With exceptional efficiency, reliability, and customizable options, ROTA Packaging Lines provide the ideal solution for pharmaceutical companies seeking sterile and particle-free packaging solutions. Each of these machines is also available stand-alone or ready for integration with existing equipment.

16773 Blvd Hymus Kirkland (Montreal),

QC Canada, H9H 3L4

Phone 514-630-1818