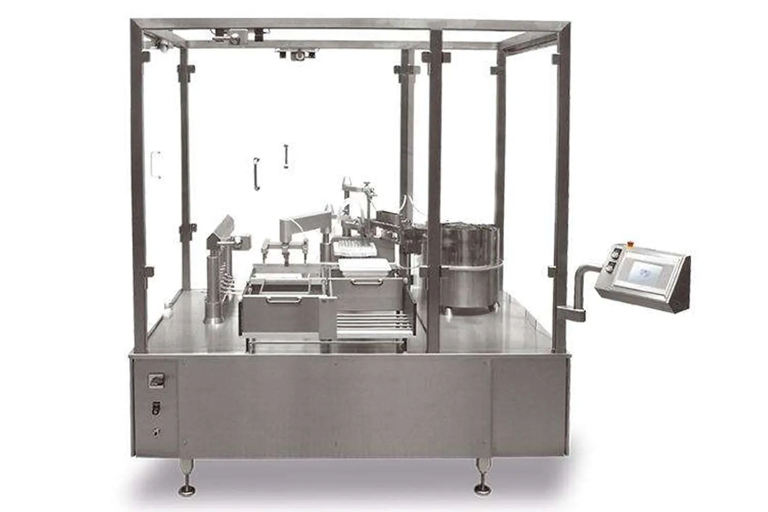

The PharmaLift is the ideal bulk feeder for integration with electronic pill counters. Our bulk feeder ensures a consistent and precise flow of products with high accuracy and can handle variations in product size. The lift will ensure the optimal amount of product is carried to the filler hopper without damage, and do so in accordance with the pharmaceutical industry’s standards for cleanliness.