A range of hygienic, high-quality stainless steel utensils available in 304 or 316L grade material, and in various sizes and styles. Including scoops, whisks, spatulas, scrapers, paddle stirrers, and more.

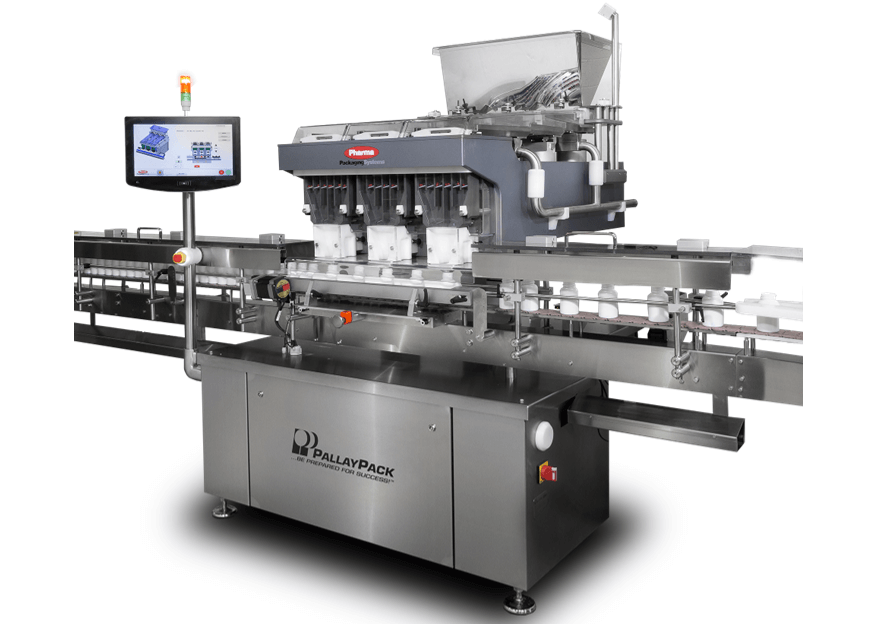

The SC180 Pharmaceutical Counter is a high-speed pill counter for tablets, caplets, soft gels, and capsules. This 18-track counter can accurately handle all pill types including translucent and opaque products. Designed for ultimate product control, you can change recipes on the fly and easily teach the machine to learn to count a variety of differently sized products. Our 18-track counter is actually a triple 6 track. The advantage of this design is that each set of 6 tracks can fill an individual bottle, resulting in significantly faster output speeds. Counters are available in various configurations including 12-track, 18-track, 24-track, and 36-track. All counters offer toolless changeover for efficiency and ease.

Pharmaceutical-grade, high speed counter for packaging soft gels, caplets, capsules, pills, opaque pills, and translucent pills.

*Note…The first speed is based on 100 counts of size 0 capsules, second speed is based on the 30 counts of 8 mm tablets.

“Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.”

A range of hygienic, high-quality stainless steel utensils available in 304 or 316L grade material, and in various sizes and styles. Including scoops, whisks, spatulas, scrapers, paddle stirrers, and more.

Bottle inverting air cleaning unscramblers are ideal for keeping up to speed with packaging demands.

Durable, easy to sterilize, re-useable, 304 or 316L pharmaceutical grade stainless steel storage, mixing, and transportation vessels. The exceptional average surface finish of 0.4 micrometers Ra leaves nowhere for bacteria to be stored and allows the most possible cleaning in the cleaning processes. 20 – 240L containers are available as standard (other sizes available upon request), and vessels can be supplied either plain or graduated (graduations are from 5L to 20L, in 5L intervals). The design is complete with side-carrying handles and a skirt band. Full Material Traceability to meet international pharma and food quality compliance regulations.

The PallayCap Capper is an automatic capping machine that combines innovative design with unparalleled performance. The PallayCap I, II, and III models offer chuck capping, pick and place cap transfer, and a unique inline indexing system. Ideal for a diverse range of containers and closures, this capper operates at speeds ranging from 10 to 80 containers per minute, ensuring precision and efficiency in your packaging process.

16773 Blvd Hymus Kirkland (Montreal),

QC Canada, H9H 3L4

Phone 514-630-1818