Specialized equipment used in the pharmaceutical industry for the purpose of mixing and blending various ingredients to create pharmaceutical products.

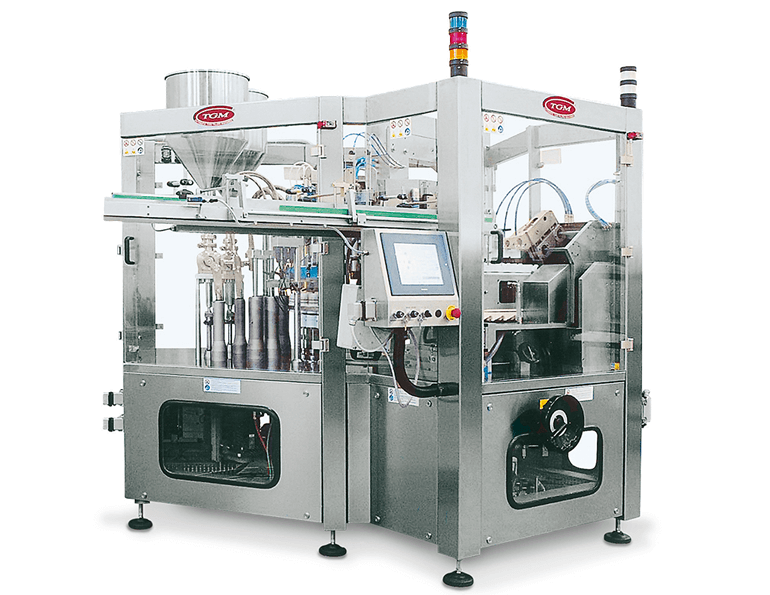

These automatic tube filling machines are equipped with large, ergonomic feeders designed for high efficiency and ease of operation. Compact yet versatile, TGM machines are capable of handling two to three tubes simultaneously, which makes them ideal for large batch production. The T230 and T242 specialize in filling coextruded, 2-3 color products, including 2-3 color deep-stripes and 2 concentric colors.

Our tube filling equipment offers advanced, high-capacity solutions for the packaging industry, particularly suitable for large-scale production. Their high-speed and automatic operation, combined with the capability to handle multiple tubes simultaneously, makes these tube fillers the ideal choice for businesses looking to enhance their production capacity and efficiency.

Specialized equipment used in the pharmaceutical industry for the purpose of mixing and blending various ingredients to create pharmaceutical products.

A range of stainless steel cans with lids, available in either 304 or 316L grade stainless steel. They come complete with stainless steel lids and swing handles, have crevice and pit-free interiors, and are polished throughout. A range of optional modifications is available.

These containers are designed and manufactured to comply with Good Manufacturing Practices (GMP) for material handling, storage of raw materials, mixing and blending, transportation of intermediates, and liquid storage.

A simple yet accurate method of counting round tablets. Manufactured from 304-grade stainless steel, these units allow the user to easily see the number of round tablets in each batch, and to quickly pour them into a container.

16773 Blvd Hymus Kirkland (Montreal),

QC Canada, H9H 3L4

Phone 514-630-1818