A simple yet accurate method of counting round tablets. Manufactured from 304-grade stainless steel, these units allow the user to easily see the number of round tablets in each batch, and to quickly pour them into a container.

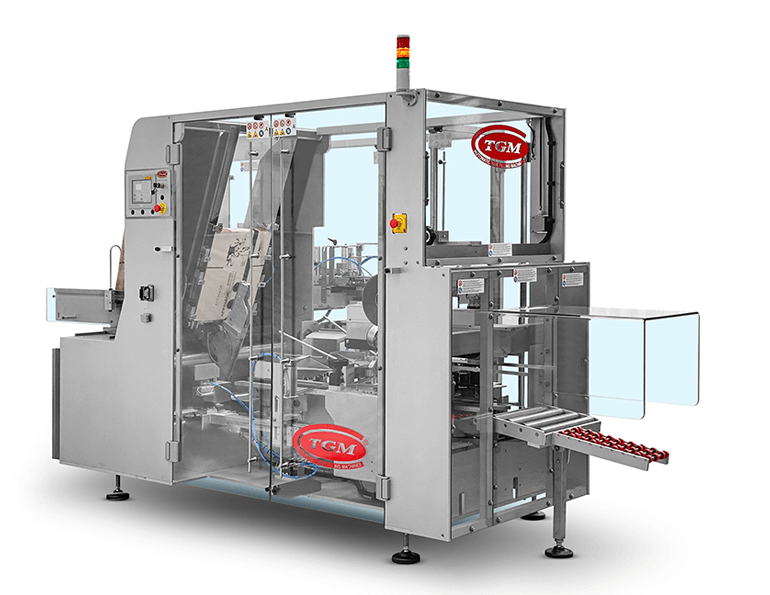

The CP02 Case Packer is a versatile and compact case packer designed to insert single cartons and bundles into cases. Its horizontal design emphasizes ease of operation and adaptability to different packaging needs. Its compact design, high-speed capabilities, and servo-driven precision make it a valuable asset for businesses in the pharmaceutical, food, and cosmetic industries looking to enhance their packaging efficiency and reliability.

Our horizontal case packers are typically more space-efficient and are easier to integrate into existing production lines. The CP02 can handle a variety of products and packaging types.

A simple yet accurate method of counting round tablets. Manufactured from 304-grade stainless steel, these units allow the user to easily see the number of round tablets in each batch, and to quickly pour them into a container.

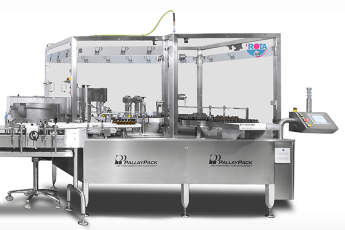

ROTA’s FLR Pharmaceutical Vial Filler Machines can be configured to fill, insert a stopper or plug, crimp cap, or screw cap depending on the application. These efficient solutions offer versatile dosing options, prevent waste, and accommodate various vial filling and closing methods to ensure precise and profitable operations for your pharmaceutical needs.

Accurately counts coated and uncoated tablets and capsules. Tablets up to a diameter of 1/2″ and capsules up to 3/4″ long can be counted using a range of 5 interchangeable perforated plates. Perspex construction aids visual checking and easy cleaning. Full withdrawal dispenses 50 to 100 tablets.

The PharmaLift is the ideal bulk feeder for integration with electronic pill counters. Our bulk feeder ensures a consistent and precise flow of products with high accuracy and can handle variations in product size. The lift will ensure the optimal amount of product is carried to the filler hopper without damage, and do so in accordance with the pharmaceutical industry’s standards for cleanliness.

16773 Blvd Hymus Kirkland (Montreal),

QC Canada, H9H 3L4

Phone 514-630-1818