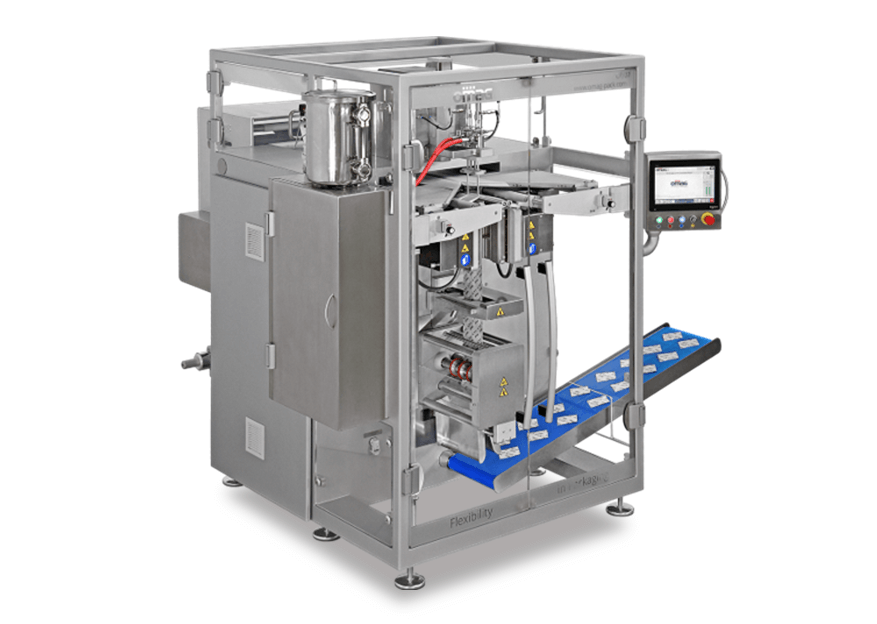

TGM offers a range of horizontal, automatic cartoning machines, each designed to cater to different production needs in industries like food, cosmetics, pharmaceuticals, and medical.

The Box90 is an intermittent motion horizontal cartoner suitable for use in medium to high volume production lines. The Box100 is an intermittent motion horizontal cartoner suitable for use in medium to high-speed production lines. The Box150 is a continuous motion horizontal cartoner suitable for use in high-speed production lines. The Box200 is a continuous motion horizontal cartoner suitable for use in high-volume production lines.

Each of these machines offers unique capabilities, making them suitable for a wide range of packaging needs. The choice of a specific model would depend on the specific requirements of the production line, including the type of product being packaged, desired speed, and the level of automation required.